Productivity is never an accident. It is always the result of a commitment to excellence, intelligent planning, and focused effort." - Paul J. Meyer

Considering the importance of productivity and efficiency, how do companies increase them? What methods do they use? Do they face any challenges?

Productivity is a measure of how effectively inputs are being turned into output.

Efficiency is described as the ability to create something with the least amount of waste as it is associated with time, capital, and resources.

What is the importance of labour productivity and efficiency?

Labor productivity measures the efficiency of the workforce, while efficiency takes into account all factors of input such as capital, workforce and other resources.

Labour productivity can be calculated as follows:

If 100 workers produce 3,000 units of output in a week, then labour productivity is 300 units per employee/week.

Efficiency can be calculated with the following formula:

If a worker's output is 350 units/week but the standard output, as per the previous example, is 300 units/week, efficiency is equal to 116.67%.

Advantages of increasing productivity and efficiency of labour

Proficient use of inputs permits companies to maximize production and hence, fulfil the requirements of more consumers.

Efficient utilization of inputs signifies that fewer inputs are required to produce a certain level of output. Therefore, reducing the unit costs for the organization.

Reduced unit costs assist in gaining a competitive advantage since the organisation can decrease its prices and still keep the same profit margins.

When consumers demand top-quality products, the cost savings, due to greater efficiency, can be utilized to enhance the quality of the products.

Efficiency will allow the organization to boost its appeal to its stakeholders.

How can labour efficiency and productivity be increased?

There are several ways to enhance efficiency:

Utilization of renewable resources: Numerous factories are constructed to minimize waste and enhance energy efficiency in order to use the resources in an effective manner.

Increase the education and training of the labour force: This will result in greater productivity and efficiency due to the newly acquired and developed skills of the labour force.

Increase the degree of investment in capital equipment: Top-quality capital products can improve the efficiency of the workforce. Companies that use the latest technology will be increasingly efficient and offer products that fulfil the rapidly changing needs of customers.

Developments in management skills and inclination for taking risks: These will considerably enhance efficiency as inputs will convert into goods that fulfill the needs of the customers.

Combination of the factors of production in a well-adjusted way: This will make sure that all inputs are utilized in an effective manner

What are the benefits and difficulties of lean production?

Lean production is an approach that emphasizes cutting waste and ensuring quality.

This approach can be used in all areas of a company. It includes a range of time-saving production and supply methods such as:

Just in time management (JIT)

Time-based management

Simultaneous engineering

Quality circles

Total quality management (TQM)

Kaizen (continuous improvement)

Cell production

Let's focus our attention on the just-in-time (JIT) approach.

JIT is a type of pull production - where production only starts when it is necessary. Instead of producing the maximal amount of a product, just in time production waits for a signal, such as an order, before starting the production of the product.

The key objective of JIT is to decrease waste by disregarding the requirement to have a high level of inventory. This will be beneficial in reducing costs through less warehouse space and costs related to the employees working in the warehouse. Lower levels of inventory will also decrease losses to an organization during a theft, damage while storing or the products becoming out of fashion.

In addition, JIT is a time-saving approach as well, because the delivery of the stocks can be done directly to the production line where it can be readily used, thus saving time spent to move them from stocks in the area to the warehouse and lastly to the production line. This will avoid the stockpiling up in the factory and save space hence, making the production line more compact.

Moreover, JIT also makes companies more flexible for consumers. Companies which have zero levels of inventory are more likely to respond to fluctuations in customer tastes and will not have to endure unsold stock in case there is an unexpected shift in the production of new products. Furthermore, inventory kept in the warehouse doesn't add any value to the organization, it will only add when it is transformed into a finished product. So, JIT shifts inventory directly to the production line, where it straightaway adds value.

Benefits of JIT

There is increased productivity as improved methods are recognized by employees and increased flexibility avoids bottlenecks. These methods boost productivity and efficiency.

There will be lower waste as well as inventory storage costs as there is no inventory prior to the production. Thus, improving the cash flow position of the organization.

There will also be better quality and more variety of products that are constantly being improved for the consumers.

The employees are more driven because there is a higher opportunity for

There will be more employee participation while making decisions resulting in improved and well-informed ideas as bigger participation means more ideas being contributed in the decision-making process.

The difficulties of using JIT

There might be fewer opportunities to purchase in bulk and capitalise on economies of scale because stocks come more often, however, in smaller quantities, which can increase costs.

If a supplier is unable to deliver one component it means the production will stall as there is no prior inventory available to use. JIT requires highly dependable suppliers or a wider range of suppliers (which is less risky).

By relying on suppliers to give greater quality raw materials, an organization is at risk if a component has faults and there is no time to test them earlier.

Difficulties of increasing productivity and efficiency

There are difficulties that restrain the effort to increase productivity and efficiency. They are as follows:

Several resources are not renewable and with increased global demand it is possible to have future shortages of vital resources.

The utilization of training and education can help enhance productivity;

A business investing in capital equipment would signify that it is diverting its resources from the production of consumer goods (that provide customer satisfaction) to capital goods (which generate future wealth).

In what ways does technology increase productivity and efficiency?

The evolution of technology has made companies be more productive and efficient over time. The following are the ways in which technologies can boost productivity:

Automation and systemization of workflow and processes

Several established companies use effective tools and applications that allow streamlining of complicated workflows and processes. These technologies have attributes and capabilities that assist in repetitive and time taking activities like collection and sorting of information or payment of bills or other monotonous tasks increase productivity and lower the possibility of human error.

Communication is easier

Since remote work remains the new way of working, cloud and mobile technologies continue to be vital to make sure that distributed workforces have a suitable resource in order to be connected and productive. In the meantime, communication and collaboration programs such as Microsoft teams, Google meet, Slack, Zoom, etc. allow the remote teams to have interactive virtual meetings, work together, and stay productive.

Allows strategic planning and time management

Efficient time management is a way to make sure that the workforce gets the most out of a day. Therefore, calendar and scheduling applications incorporate nearly any type of productivity app and are promptly available on any device.

Technology enables better focus

While technologies can do several other tasks, people can focus more and have continuous work periods, hence making them more productive. Thus, it is important that the business selects the right form of technology that meets the prevailing processes, workflow, and culture of the business.

Technology increases operational efficiency in the following ways:

Inventory management

If a retail store or a warehouse holds and manages inventory, it will be essential to know the amount of stock available and its worth. An inventory management system can support the business to run efficiently and ensure the correct level of stock. The software can also guide the staff on the location of the item in the store/warehouse. It will facilitate in maintaining stock at an optimum level by considering the volume of sales, time of the year, and forthcoming promotions.

Project management

A project management software can assist to create a breakdown structure of the work that will arrange a bigger project into small achievable tasks. With the progress of the project, the software can trace which tasks were completed and if there is any inconsistency between what was planned and the real-time and material utilized for every phase. The software will show if there is any variation in the actual budget and the planned budget, hence, appropriate actions can be taken to make sure that the project is profitable.

Dashboard and measurement of metrics

In order to develop efficiencies in the operations, it is essential to know how the business is doing and be able to measure the performance in comparison to the yardstick. Dashboards accessible to the managers and the employees can considerably enhance awareness of the performance of the company. They also support the employees in realizing the vital part it plays in the success of the business, enabling them to be more engaged in operational efficiency enhancements.

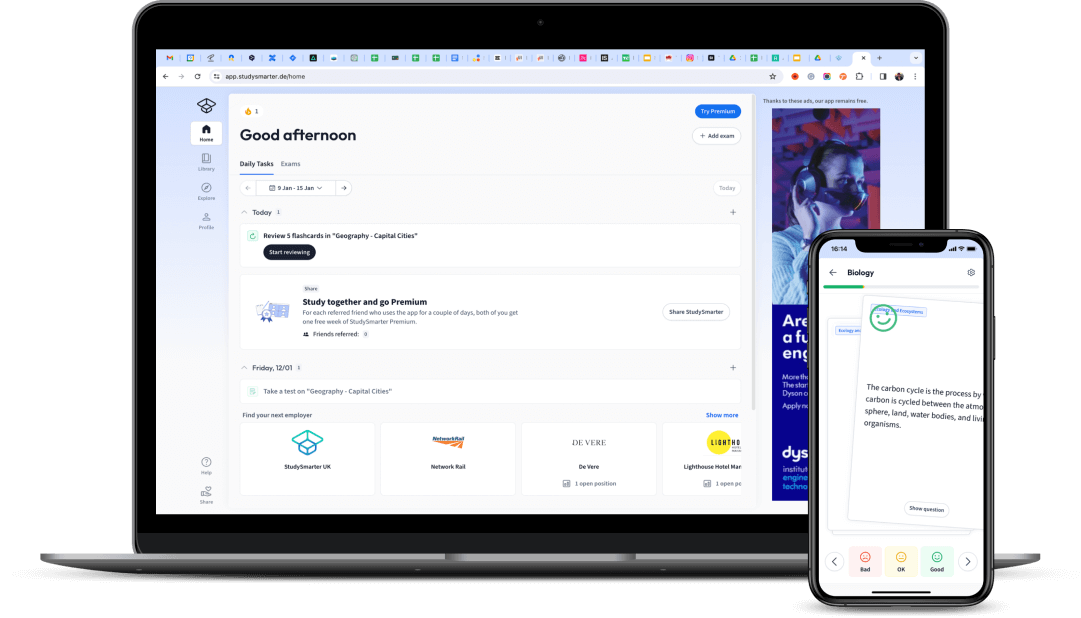

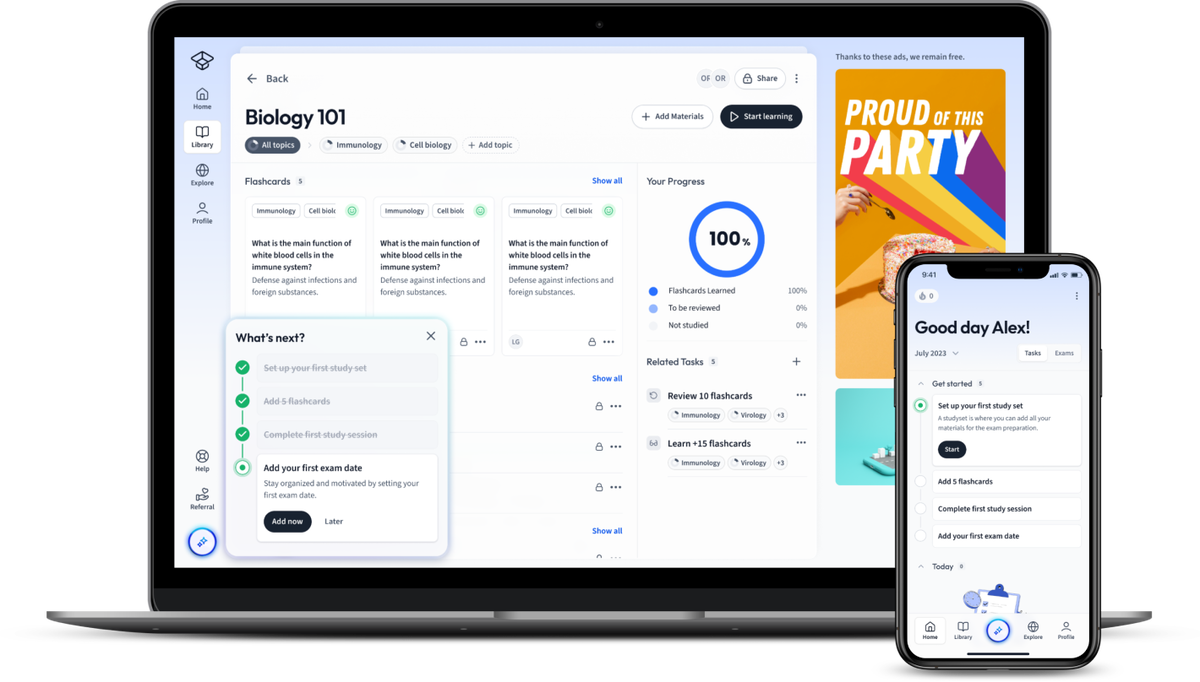

Figure 1. The way technology increases productivity and efficiency, StudySmarter

How to choose the optimal mix of resources

The resources an organization uses are usually called factors of production such as labour, land, enterprise, and capital. Labor and capital are usually being used interchangeably in production; Hence, an organization should choose if its production will mainly be dependent on the use of labour or capital.

Factors affecting the choice between capital- or labour-intensive production

In labour-intensive production, human labour is the primary means of production. While capital-intensive production is dominated by machinery and equipment.

A company will consider different factors prior to the decision of using capital-intensive or labour-intensive production. Some of the factors are as follows:

Methods of production

If there is mass production of cars for instance, then it will need capital equipment that will be quicker and more consistent in comparison to a human being. This means the company will go ahead with capital-intensive production. However, if the products are tailor-made for consumers, then labour-intensive production is likely to be used.

Skills, competence, and efficiency

A company (hair salons) that relies on the skills of its employees will choose labour-intensive methods. But, if capital can significantly reduce unit costs or produce a more reliable and higher quality product, then it is more likely that capital-intensive methods will be used.

Size and financial situation of the company

It is very costly to buy capital equipment. Small companies will not be able to buy the equipment required for capital-intensive methods. So, they will decide to use labour-intensive production methods.

Standardised goods

For standardized products/services, capital-intensive production methods can produce larger quantities at lower unit costs.

Productivity and efficiency - key takeaways

- Productivity is a measure of how effectively inputs are being turned into output.

- Efficiency is described as the ability to create something with the least amount of waste as it is associated with time, capital, and resources.

- The advantages of labor productivity and efficiency are an efficient use of inputs, reduced costs which assist in gaining competitive advantage, greater product quality, among others.

- Labor productivity and efficiency can be increased by utilizing renewable resources, increasing education and training of the labor force, investing in capital equipment, and combining the factors of production.

- Lean production is an approach that emphasizes cutting waste and ensuring quality.

- The key objective of JIT is to decrease waste, reduce costs, save time, provide flexibility and add value.

- The benefits of JIT have increased productivity, the workforce being more motivated and lower labour turnover, more employee participation contributing to more ideas, lower waste and inventory storage costs, and better-quality products.

- Difficulties with JIT are that there is no bulk-buying opportunity, a halt in production if suppliers fail to deliver, a company is at risk if there are faulty components.

- Difficulties to increase labor productivity and efficiency are resources are not renewable, opportunity cost with education & training with time and investment in capital equipment diverts the resources.

- Technology boosts productivity by systemization of processes and workflow makes communication easier, allows strategic planning and time management, and it enables better focus.

- Technology increases operational efficiency through inventory management, project management, dashboards, and measurement of metrics.

- The choice between labour or capital intensive production depends on methods of production, skills and efficiency, size and financial position, and standardized products.

Explanations

Exams

Magazine