Have you ever wondered what happens behind the scenes of a business and how its products are supplied? How do businesses manage to get their raw materials and products in time for production and supply? This is where inventory management comes into the picture with the sourcing and storage of raw materials and products. We will look at two major methods of inventory management, so read along to identify which is used by your favourite shops.

Just-in-Time Stock Management

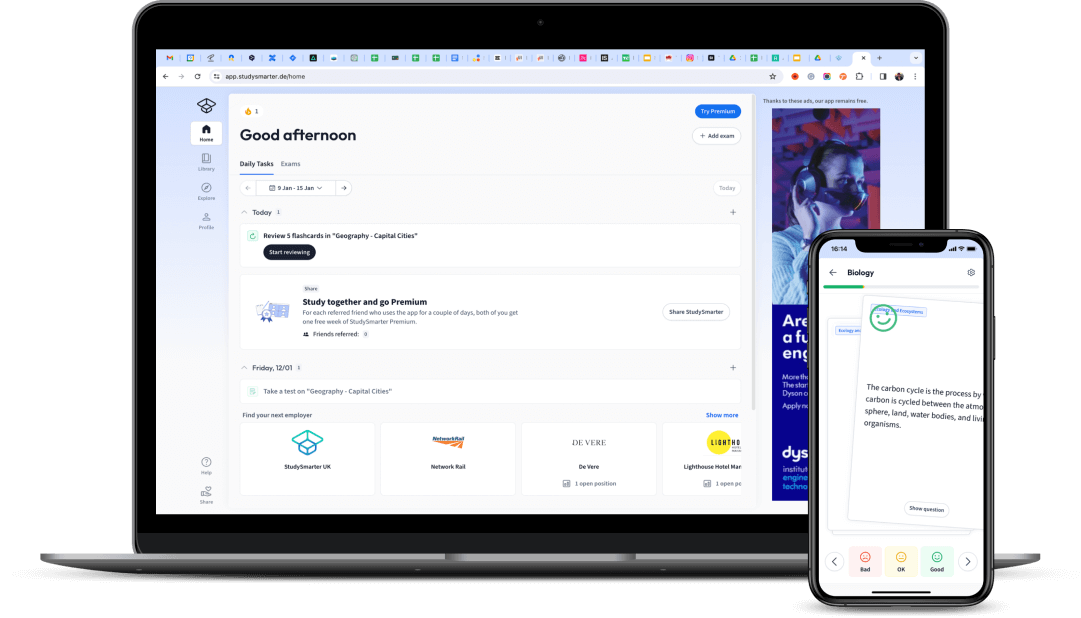

All businesses hold stock of raw materials, finished goods, or both. Just-in-time inventory management is an approach to managing stock, seeking to reduce the amount of stock held by a business. As the name 'just-in-time' implies, the stock used arrives just in time to be used in the production of finished goods.

Definition of Just-in-time Inventory Management

Inventory management is a systematic way of sourcing, storing, and selling raw materials and finished goods. It involves the process of sourcing raw materials used for production and storing finished products manufactured by the business.

Inventory management is a part of the procurement or purchase stage in a business, which involves choosing suppliers and negotiating contracts with them in regard to stock, payment, and delivery.

Inventory management can be defined as a set of practices used by a business to control its stock in terms of raw materials and finished goods and manage the current and future stock requirements of the business.

Just-in-time is a type of inventory management. As the name implies, the stock arrives just in time to be used to produce finished goods.

Just-in-time (JIT) inventory management is a method of inventory management that seeks to minimize and avoid waste. This method ensures that the stock required by a business for production is supplied just in time as required, and raw materials are delivered just in time for production (see figure 1).

Just-in-time inventory management is often regarded as a more efficient inventory management system than others. It aids in improving productivity for businesses, and minimizes cost. It also eliminates overproduction and excess inventory and ensures quality control of finished goods. This method of stock control ensures that the demand for a product is met only as it is required.

Fig. 1 - An order finished and packed after receiving the order

Fig. 1 - An order finished and packed after receiving the order

An example of a brand that operates with this method of inventory management is Zara. Zara is a fast-fashion brand with the competitive advantage of being able to meet market demands quickly. The store managers order clothes in small quantities twice a week based on the demand of consumers. This allows Zara to sell its goods at full price and meet an ever-changing demand, one of the characteristics of the fashion industry.

Key features of Just-in-time Inventory Management

Stock arrives when the business needs it during production.

Long-term contracts are entered with suppliers, which builds strong relationships.

Cost is minimised, which eliminates overproduction and waste such as renting warehouse space.

A warehouse is a building or a space used for storing goods mostly used by businesses, manufacturers, etc. This method of inventory management aids in reducing or eliminating the use and cost of using a warehouse because orders for raw materials or finished goods are only placed when needed during the production process. There is no need to store extra raw materials or finished goods in a warehouse, as the business orders the exact amount needed at a time and repeats this same process at every point of production or distribution.

Businesses keep control over the supply chain.

Finished goods maintain their scarcity and exclusiveness.

It ensures and encourages product quality in the form of continuous improvement via lean management.

Lean inventory management is an approach used to increase a company's inventory value by minimizing or eliminating material, effort, and time waste.

Lean inventory management is a quality control management approach with the aim of improving productivity by eliminating eight types of waste in the manufacturing process: defects, overproduction, waiting, unused potential, transport, inventory, motion, and extra processing time.

Lean production can be achieved through continuous improvement, by continual monitoring of the workflow in a business process, and assessment of areas with obstacles and need for improvement. Monitoring the workflow can aid a business in identifying what has been done and what needs to be done. This step can help future processes improve and reduce mistake repetition.

Just-in-time inventory management is a tool that can be used in lean production, as it aids in curbing excess inventory. Lean production uses efficiency to add value for consumers, while just-in-time is focused on the efficiency of the business.

Advantages of Just-in-time Inventory Management

Cost reduction: This approach to stock control has the advantage of cost reduction to a business. As less stock is held and only requested when needed during the production process, there is no need or cost to bear for the use of a warehouse.

Determination of price: This method of inventory management is great in terms of pricing. Finished goods are made on-demand and based on the stock of raw materials ordered, so the business does not experience pressure to sell out overstock by reducing the price.

Less production mishap: Due to the fact that stock arrives just in time for the production of goods, the likelihood of making mistakes is less. Errors in production are less likely to happen as the products are made just in time to fulfil orders.

Less damage: As the stock is ordered during the production process and only the required amount is ordered from suppliers, the likelihood of damage to stock and finished goods is less. There is no need for the warehouse to store excess stock and finished goods, so the possibility of an accident affecting the raw materials and finished goods in storage is minimal.

New trends: This method of inventory management enables a business to meet up with new trends or changes in the demand pattern of consumers, as they can bring products to the market quickly.

Disadvantages of Just-in-time Inventory Management

High demand: A business might not be able to produce enough to match a demand higher than what has been planned for, as they do not have access to an inventory of goods. It will not be able to meet urgent or immediate demand requirements.

Unforeseen circumstances: Unforeseen circumstances might arise that can affect the delivery of stock. These may include natural disasters or the inability of suppliers to meet the intended date of stock delivery. In addition, the requested quantity can affect the ability of a business to produce finished goods and meet up the demand of consumers, leading to a loss of profit.

High transportation cost: While this method of stock control aids in minimizing the cost incurred by businesses, transportation costs will be high. Businesses need to order more often as they do not hold inventory.

Loss of economies of scale: Typically, a business achieves economies of scale when production increases. Costs then decrease as they are spread over a large number of goods. Here, due the small number of goods produced only when required, this does not take place. Bulk order discounts from suppliers can also prompt economies of scale, but businesses using JIT do not bulk order.

Just-in-case approach Inventory Management

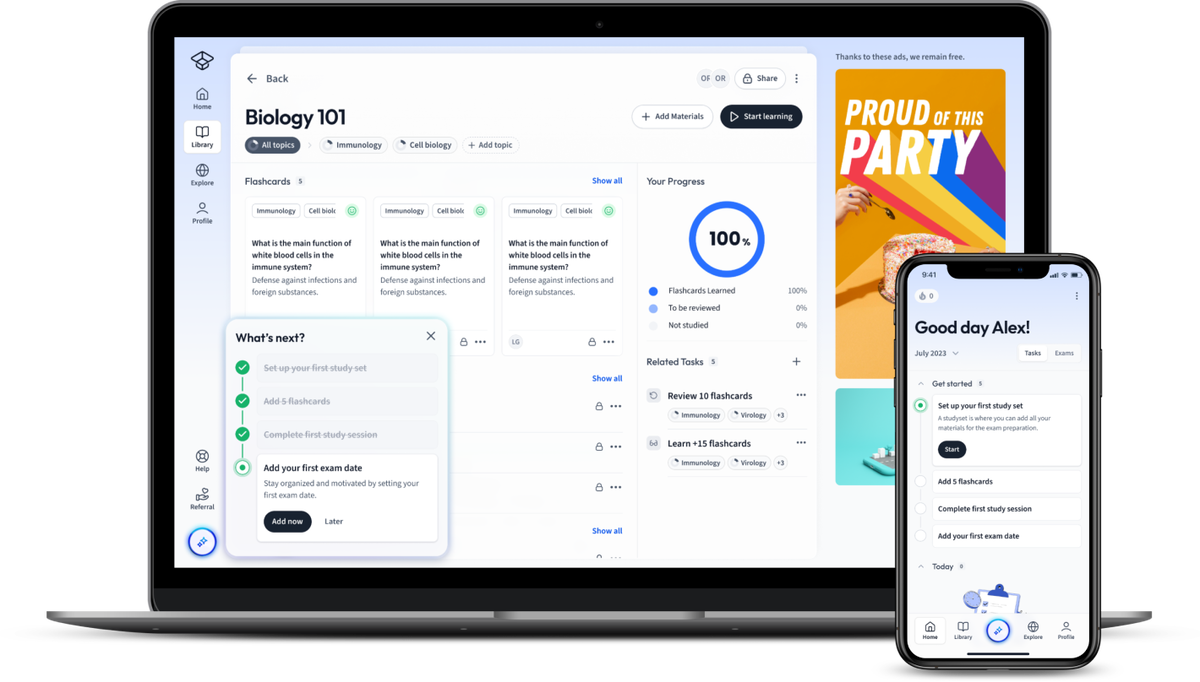

This is a different approach to inventory management used by a lot of businesses in the past. This approach involves holding stock just in case it is needed. Just-in-case inventory management involves bulk buying and always having raw materials easily accessible to the business for production.

Just-in-case (JIC) is an approach of inventory management in which a business orders more stock than is required at the moment of production. Businesses that use JIC have large inventories of products, as seen in the image below.

Fig. 2 - Products being manufactured and stored before receiving an order

Fig. 2 - Products being manufactured and stored before receiving an order

Key Features of Just-in-case Inventory Management

Bulk buying: A business that adopts this approach bulk buys raw materials and stores them for future production purposes.

Economies of scale: This approach leads to purchasing economies of scale, in which buying in bulk leads to lower prices per unit due to either a bulk discount or a reduction in the cost of transportation.

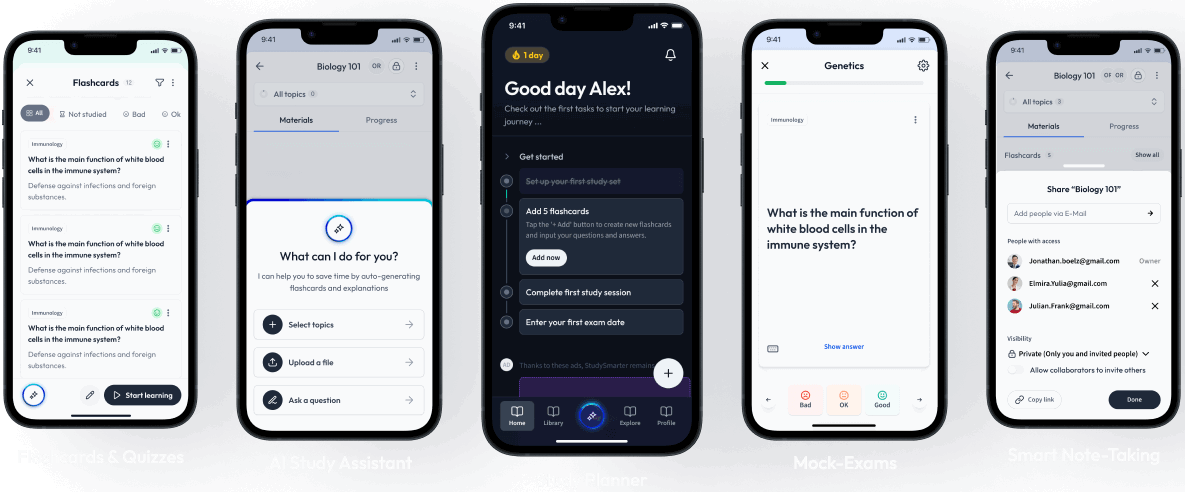

Difference between Just-in-time and Just-in-case Inventory Management

When using just-in-time inventory management, a business receives inventory only when required for production and not ordered in bulk in anticipation. Companies utilise this method to curb and reduce excess supply and avoid waste. Companies using JIT also utilize their capital more efficiently, as it is not tied down in stock, which allows the business to invest in other areas such as research and development, technology, etc.

When using just-in-case inventory management, on the other hand, the business stocks up on raw materials ahead of production. This approach makes it possible to meet large demand, and unexpected orders arising from unforeseen circumstances. These may include natural disasters, weather, high fuel prices, or any other factors that might affect the delivery of stock. However, the heavy stocking of materials is inefficient in terms of capital and investment possibilities for businesses.

| Just-in-Time Inventory Management (JIT) | Just-in-Case Inventory Management (JIC) |

| 1. Receives inventory when needed for production | 1. Receives inventory ahead of time |

| 2 Optimizes lean management by reducing waste in manufacturing | 2. Minimises the chance of low stock |

| 3. Goods are produced upon order; order precision | 3. Goods are produced just in case; order anticipation |

JIT and JIC are the two main approaches to inventory management and neither is superior to the other. It is up to the business to pick the inventory management approach best suited to its business strategy and model.

Just-in-time Inventory Management - Key takeaways

- Inventory management can be defined as the set of practices set up by a business to control its stock in terms of raw materials and finished goods, and to manage the current and future stock requirements of the business.

- Just-in-time inventory management is an approach to inventory management that encourages efficiency.

- The just-in-time approach aids in waste reduction.

- Just-in-time inventory management is not necessarily better than the just-in-case approach.

- Just-in-time inventory management can be beneficial, as the firm reduces its costs in terms of warehouse fees, sets the price without pressure to sell old stock at lower prices, and is able to be reactive to new trends.

- On the other hand, firms operating the just-in-time method might experience an inability to meet high demand due to lack of stock, high costs of transportation, or unforeseen circumstances such as delays in delivery due to weather.

- Lean production is an approach that focuses on improving process performance. This quality management method improves efficiency by eliminating eight types of production waste.

- Some key features of Just-in-time inventory management are reduction of waste, improvement in productivity, and control of the supply chain.

Explanations

Exams

Magazine